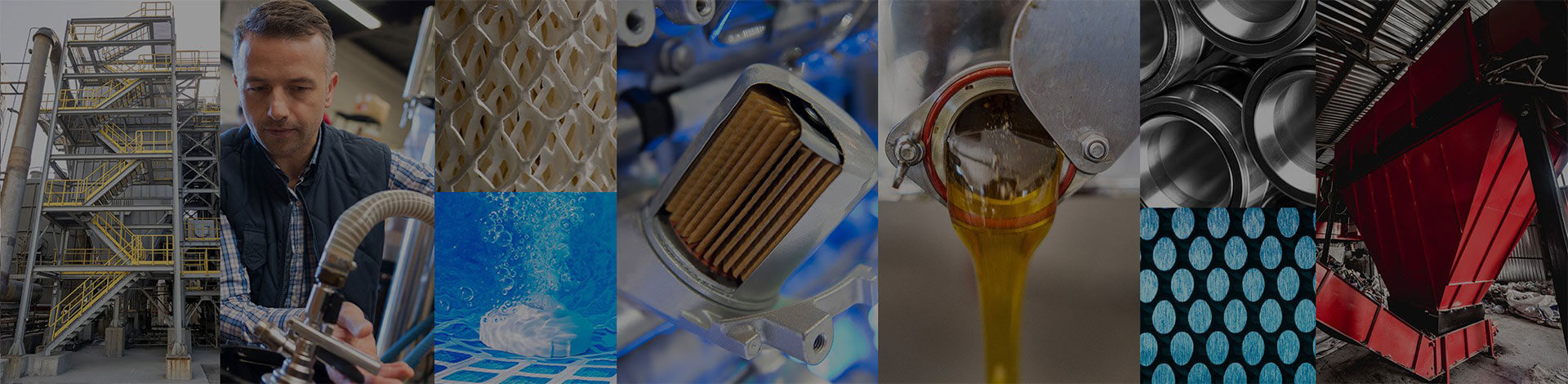

A seal for every filtration use case

Filter housings and replaceable elements utilize static and semi static seal designs configured in face seal, radial seal, piston seal or bore seal applications and include specialty vent seals, lathe cuts, square cuts, square seals, primer seals, flow control and backflow prevention seals, lip seals and u-cups. There is a specialty filter for every industrial application, from food and beverage through biopharma, high purity gas, hydraulics, fuels, CCV (crank case ventilation, and sanitary systems). Elements are paper, porous membrane, porous plastics, meshes and so on. While each filter is optimized for its intended use, the seal profiles and materials have to work with the intended media while maintaining acceptable long term compression set resistance, permeation performance, purity, and optimal interference fit for predictable installation/filter change out.

.jpg?width=617&height=412&name=shutterstock_1417332650%20(1).jpg)

.jpg?width=493&height=482&name=shutterstock_140530219%20(1).jpg)