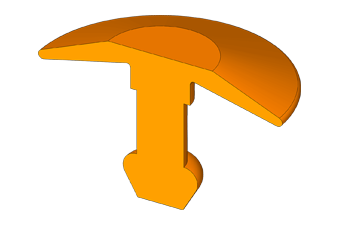

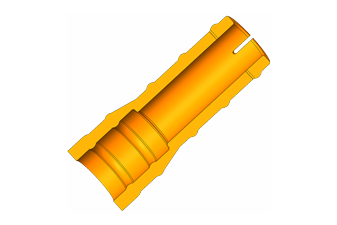

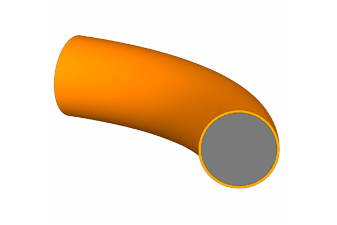

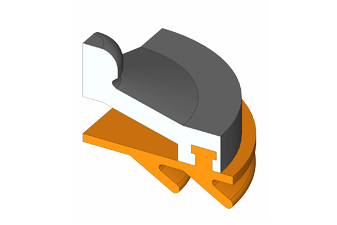

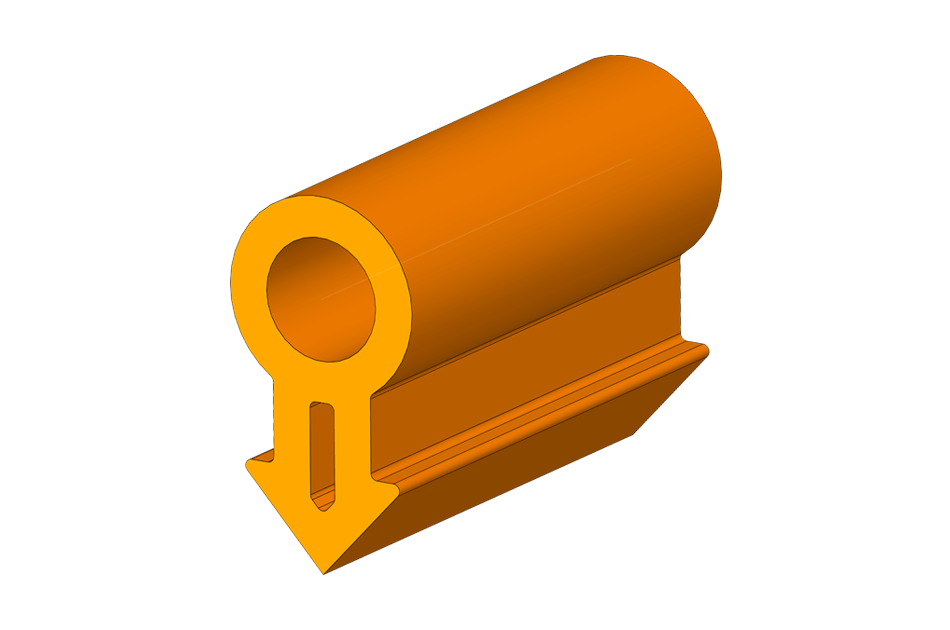

Co-Extrusion

Featuring an extruded profile shape made up of homogenous elastomer combined with property-modified elastomer. This allows cost savings by using lower cost bulk material while offering the functionality of conductive critical surfaces.

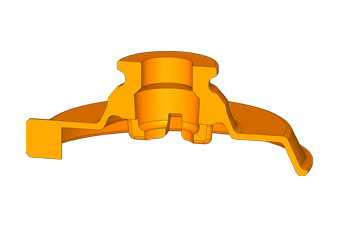

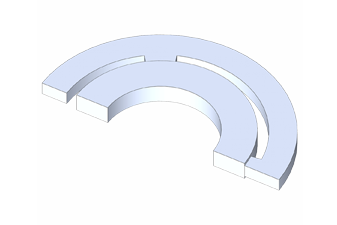

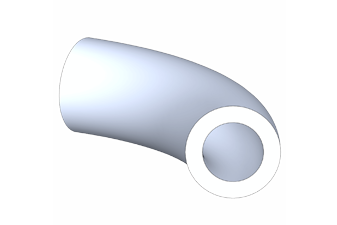

Special Applications

More Information