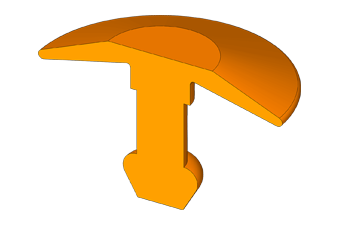

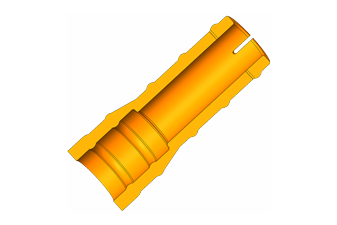

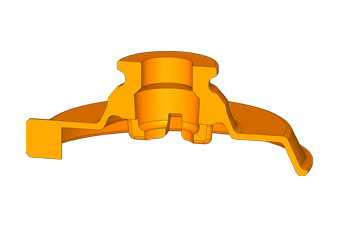

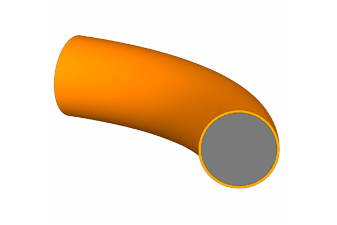

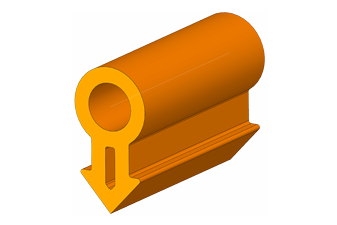

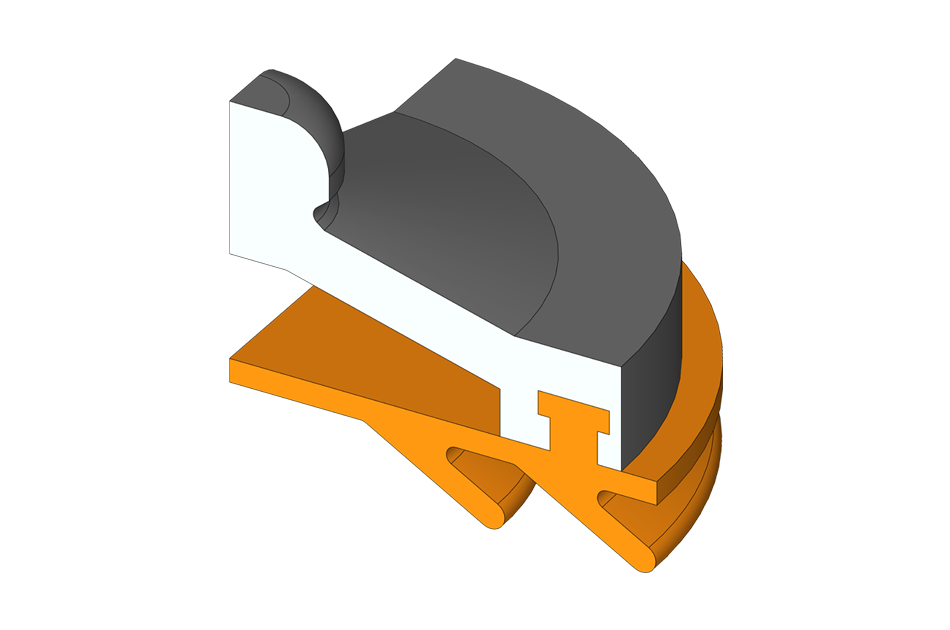

Overmolded

TPE or elastomer design element overmolded onto structural substrate such as thermoplastic. Frequently associated with molded shapes which may be adjacent to primary seal function. Typically injection molding.

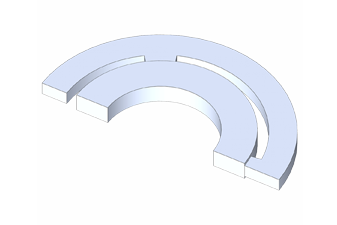

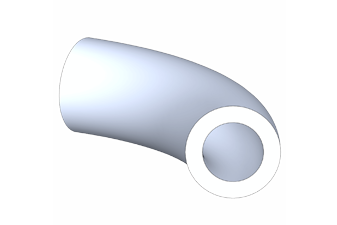

Special Applications