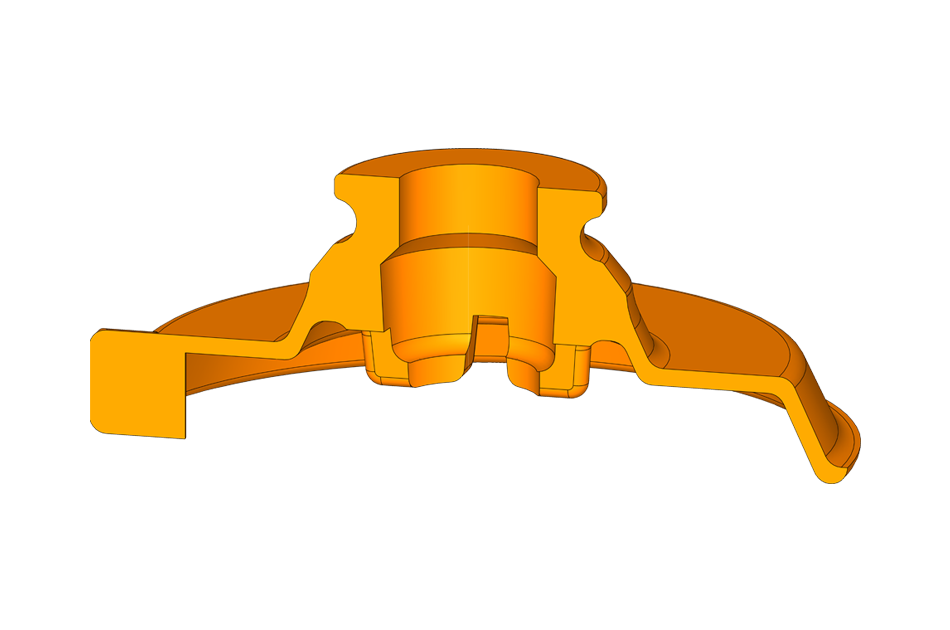

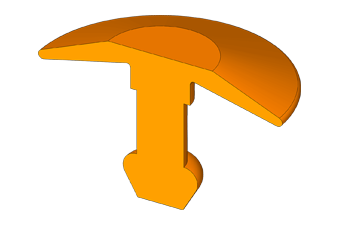

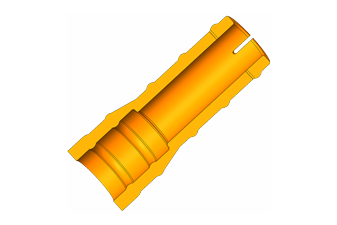

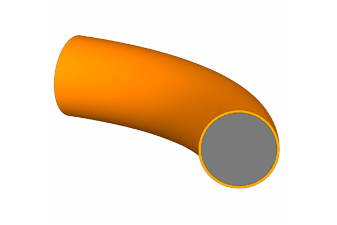

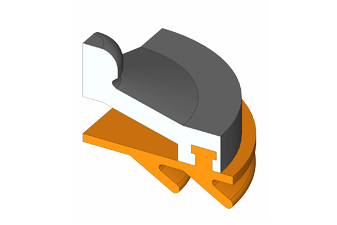

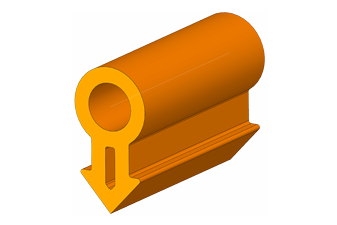

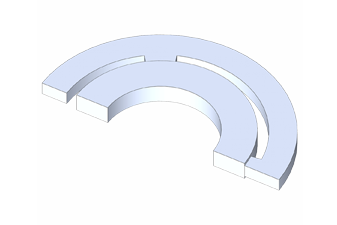

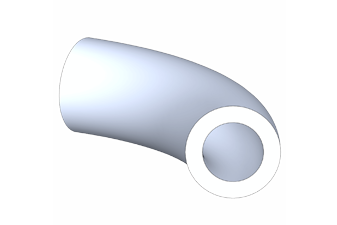

Custom molded seals are available in a virtually infinite range of shapes and cross sections. Darcoid works with best-in-class manufacturing partners to design and manufacture engineered elastomeric shapes for sealing systems and isolation applications. These seals are designed to work as individual components, or in combination with other sealing products in a system. Typically liquid injection molded silicones for medical devices thru transfer and compression molded fluorocarbons, nitrile, EPDM, HNBR etc.