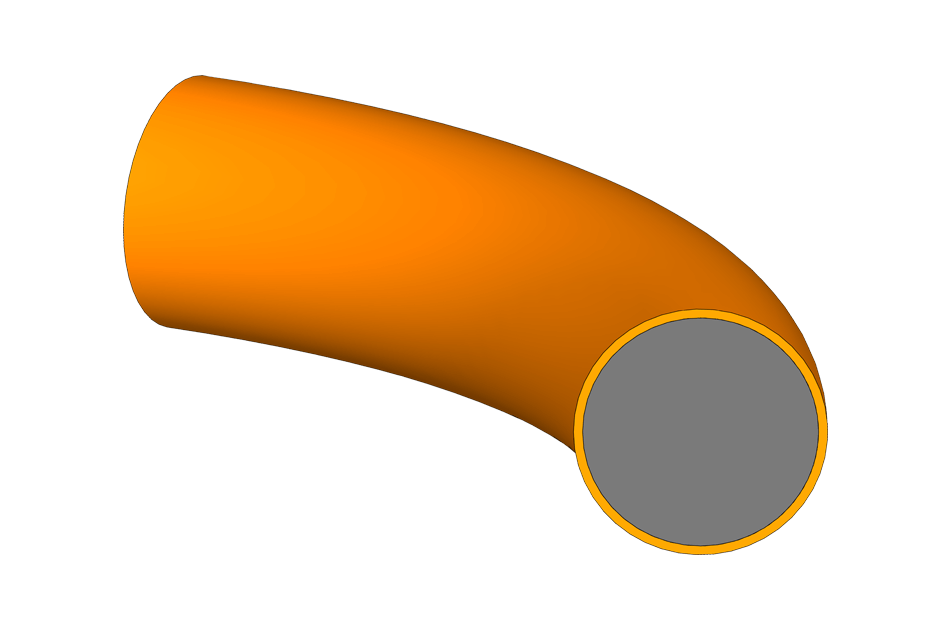

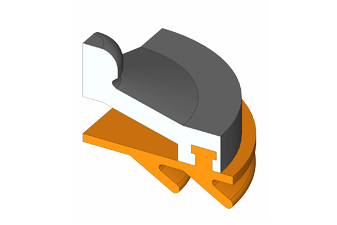

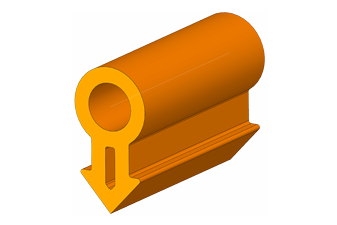

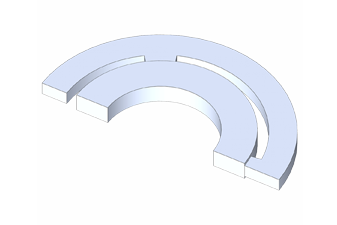

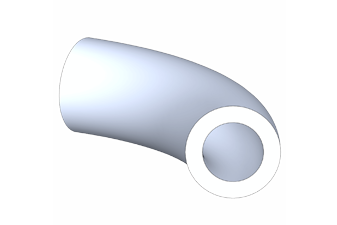

FEP Teflon sheath surrounds elastomer core providing outstanding chemical resistance without concerns for PTFE cold flow. Standard o-ring dimensions for installation in standard o-ring grooves. Typically static seal applications. Energizer core materials are typically FKM and VMQ.