.webp?width=600&height=338&name=SEAL_04%20(1).webp)

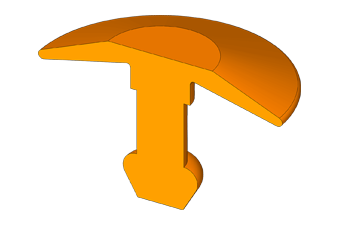

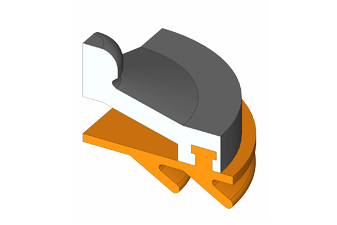

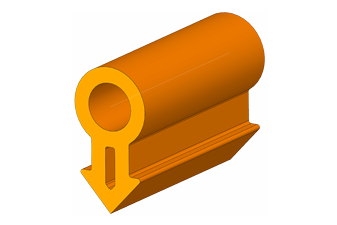

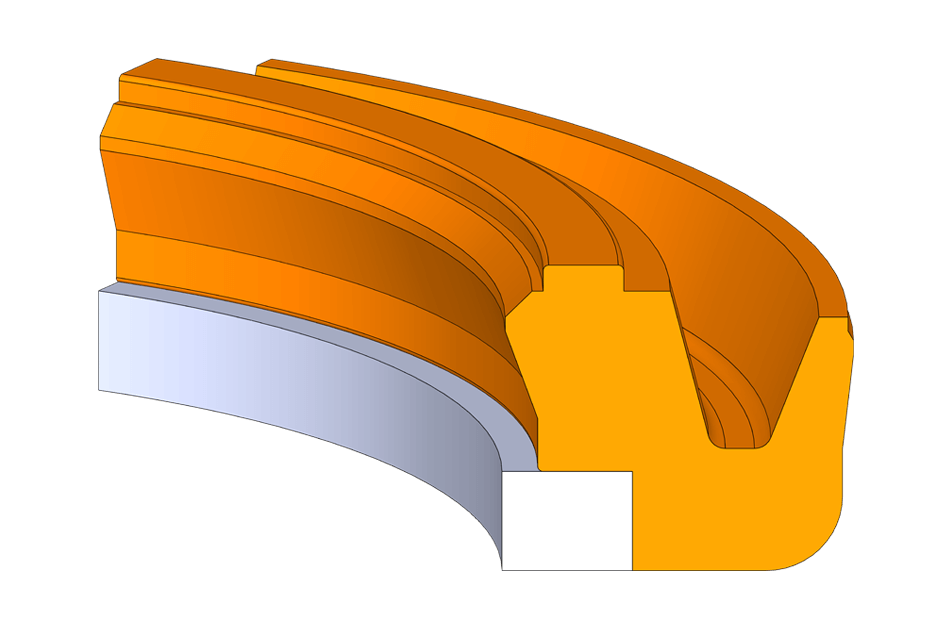

Buffer Seal

Available in various configurations, buffer seals are used in “dry critical” seal applications, or where very long seal pack service life is required. These seals may allow some low pressure leakage which is contained by the adjacent main pressure seal. The design allows pump back of intermediate fluid to avoid pressure traps.

Use in front of main seal to buffer the main seal from pressure extremes. Allows main seal to operate in a narrower envelope to assure a long life dry seal pack. Fluid bypassing buffer is trapped at main seal. Slotted/releif design on buffer facilitates "pump back" of this fluid, avoiding any instance of "pressure trap"