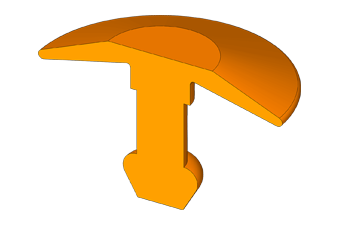

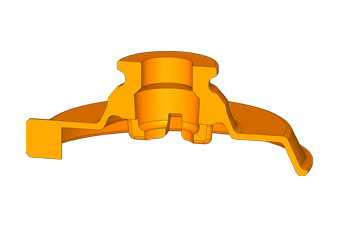

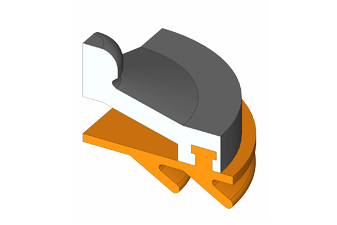

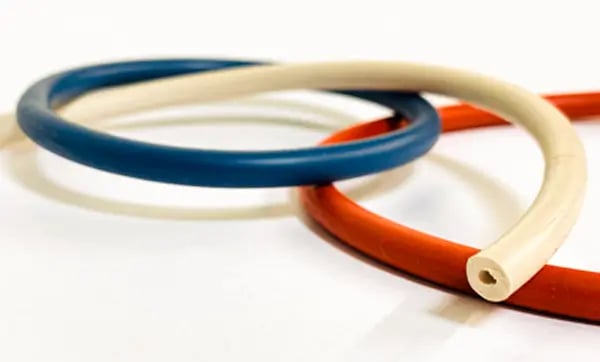

Popular option for low closure force applications. Excellent replacements for foam or sponge gaskets, offering superior compression set resistance. Interference-fit designs for ease of assembly in seal grooves without adhesives or mechanical retainers. Limitless design options by adjustment of cross-section wall thickness and material durometer.

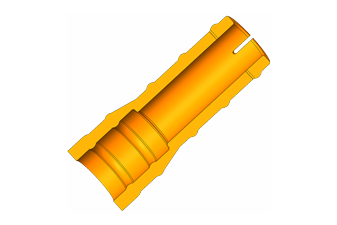

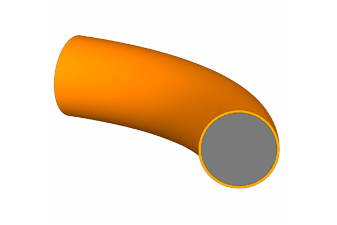

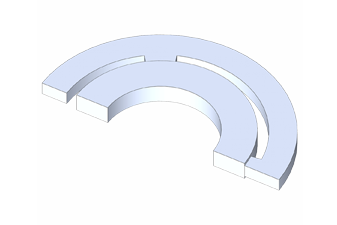

Seal cross sectional wall thickness in industry standards but the extrusion manufacturing process allows for near infinite size selection. Limitations on minimum ID of finished seal based on cross sectional dimensions. Unlimited upper end ID of finished seal.

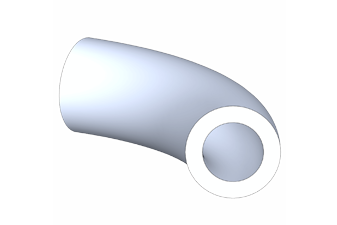

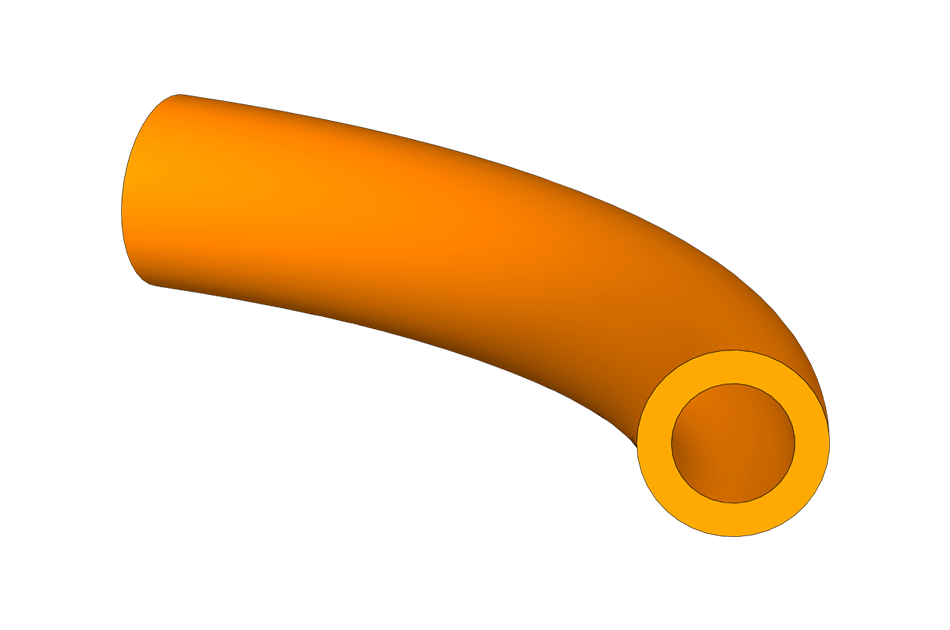

Hollow o-ring cross section performs differently under load than homogenous solid cross sections allowing for narrower gland than standard o-ring, and different interference fit considerations. Engage with our technical team to learn more.

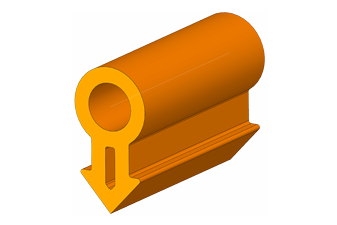

Venting, center core, custom center profile