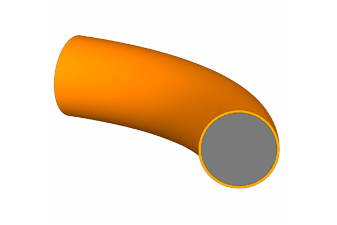

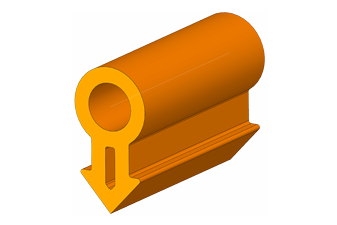

O-rings are the most commonly used seal in the world. Darcoid stocks one of the most complete and exhaustive lines of O-rings in the industry and has the widest support and availability of major o-ring seal manufacturers worldwide. Standard O-ring catalog sizes can be configured for most applications but thousands of non standard / custom Inside Diameter and Cross Section combinations are available for special applications. Darcoid can provide fast prototype molded o-ring seals in two weeks or less for unique dimension/material combinations.

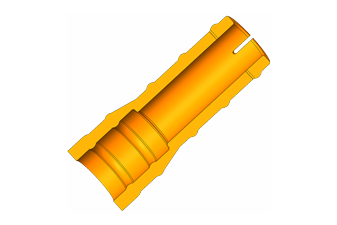

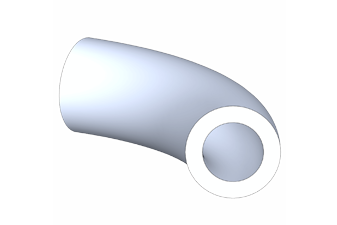

AS568-xxx, Parker 2-xxx, Parker 3-xxx, Parker 5-xxx, JIS B2401, BS1806. Custom cross sections (CS), custom inside diameter (ID) and tight tolerancing are available. Darcoid has access to many thousands of non-standard sizes for which tooling is already in place. Sizing for homogenously molded o-rings is limited by press platen size. Where larger seals are needed, we can utilize a variety of fabrication hacks, including surpentine molding, continuous molding, and splice joined from extruded cord.

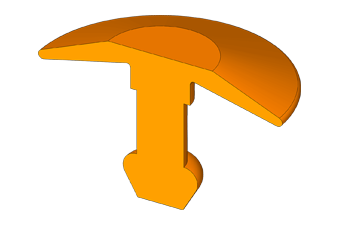

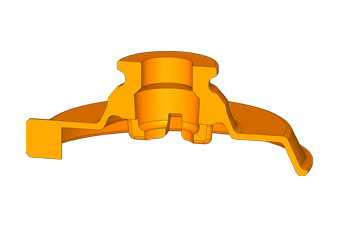

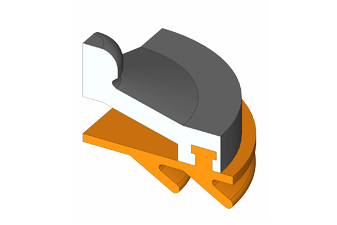

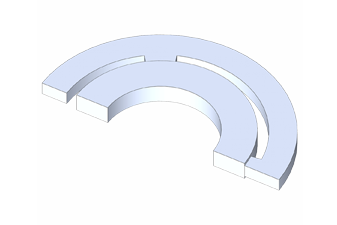

To extend the operational pressure rating backup rings are available. These act as anti-extrusion devices. Standard size and profiles are available in split or solid configurations depending on your use case. Brand names include "Parback" from Parker. Work with our applications engineers to confirm the modifications necessary to your gland sizing and determine the best backup material and profile for your application.

Materials and workmanship standards including FDA White List, USP Cl VI, WRAS, NORSOK, NSF 61, UL, NSF 51, EC 1935, NAS 1613, AMS3304 (VMQ), MIL-R-25988 (FVMQ), AMS-R-83248 (FKM), AMS7257 (FFKM)

We have millions of seals in stock and thousands of size/material combinations available through our network. For unique size and material combinations use our Rapid Prototype Program and we will ship in 2 weeks. Compression molded parts from production capable tooling. Contact us for details.