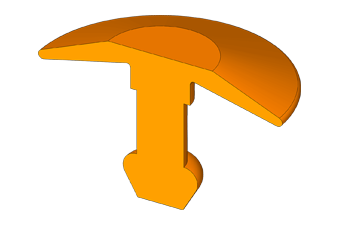

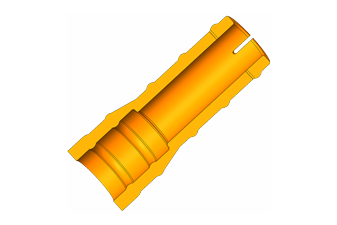

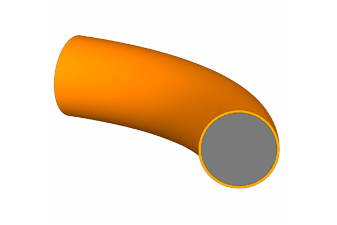

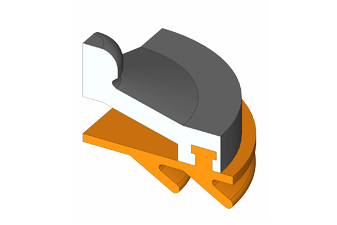

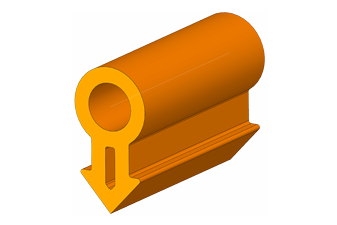

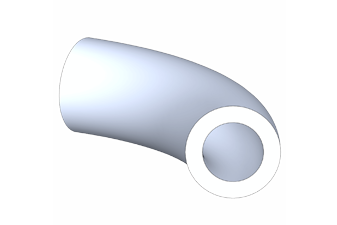

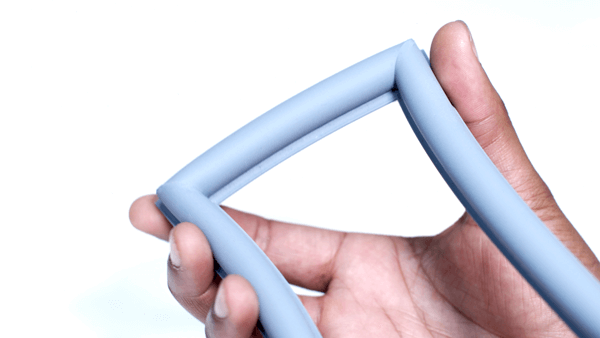

Shaped Extrusion

Elastomer extrusions are available in standard profile groupings including: Bulb seals, P-seals, D-seals, E-seals, and Omega-seals. Additional profile modifications can include barbed retention features, or secondary application of pressure sensitive adhesive (PSA).

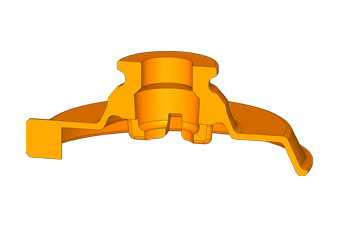

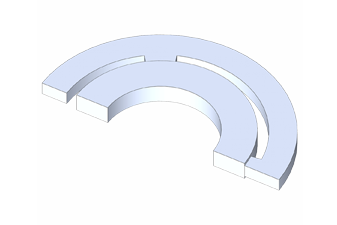

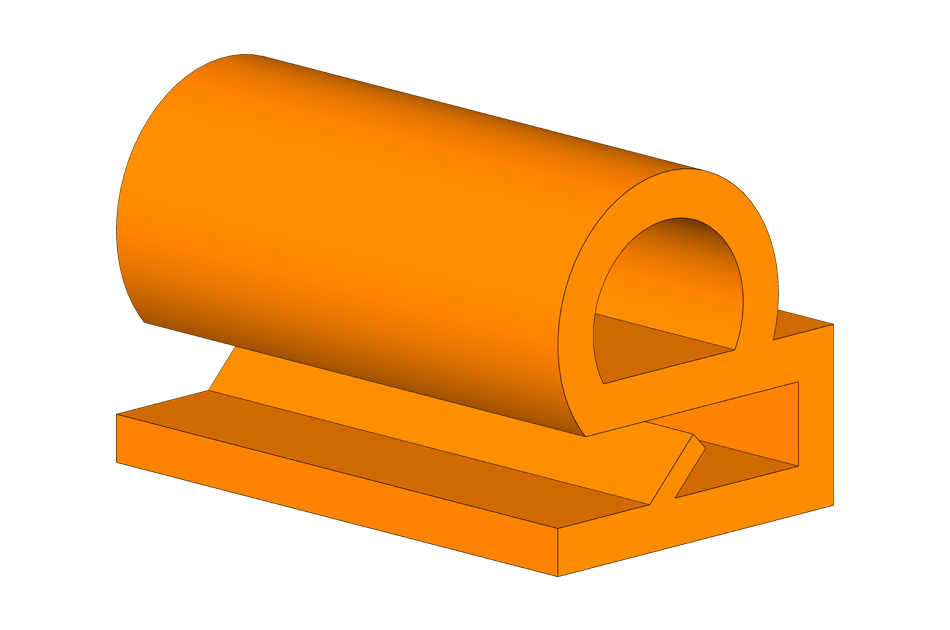

Special Applications

More Information

Metal bonded, bolt holes, PSA pressure sensative adhesive backings