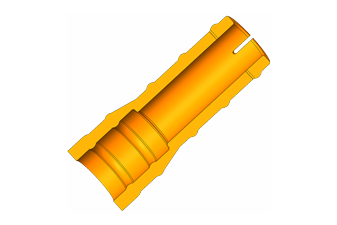

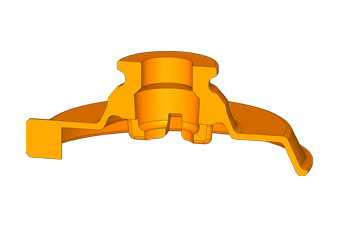

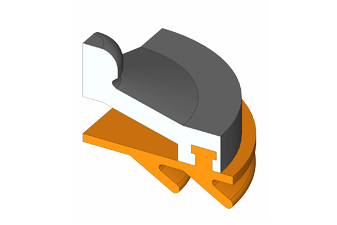

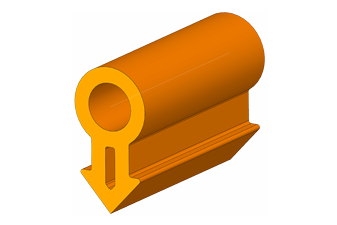

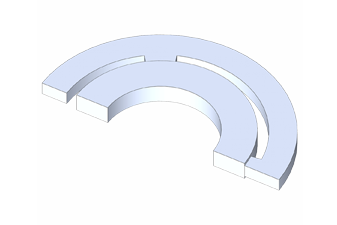

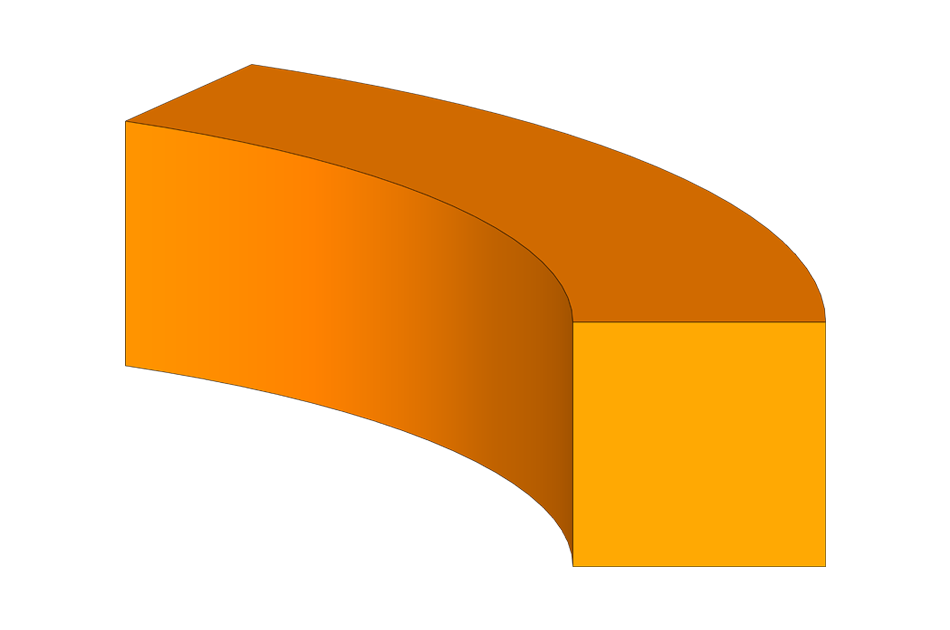

Square Seals describe rectangular cross section seals. These are typically used as static face seals, static radial seals, bumpers, sleeves, dampeners, etc. They are manufactured by lathe cutting (“Lathe Cut seals”) or by die cutting (Die Cut seals). Lathe cut square seals are manufactured from a sleeve of rubber mounted to a mandrel and turned, with individual seals parted off using a radial cutting process. Die cut square seals are cut from sheet stock using a stamp die.

Our Zund XY table cutter can generate parts within hours of receiving your solid model. For die cuts we can start running parts in days. We've had success with turning production volumes of lathe cuts in under 2 weeks. Product complexity, materials availability and prevailing supply chain conditions drives results on an ongoing basis.

A variety of parting and surface profiling options are available to provide a wide variety of custom surface features. We enjoy a challenge - what's on your mind?